Injection Stretch Blow Moulding (AOKI/ASB)

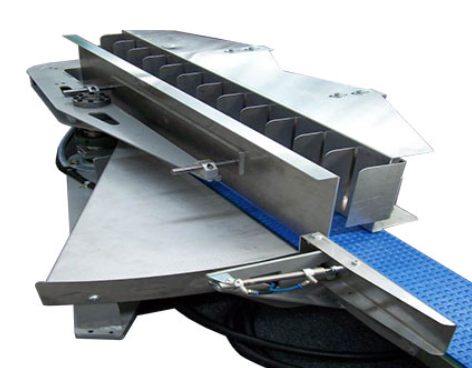

Pacwel take out units for AOKI Injection stretch blow moulders are installed inside the AOKI to capture the container as it is ejected. It then swings to place the container onto a conveyor that runs parallel to the operator side of the AOKI to exit the machine where it can then be leak detected and packed. Unlike other Mechanical or robotic systems the Pacwel unit has virtually no footprint other than the exit conveyor. As the Pacwel take out unit is designed to operate inside the AOKI, each unit is specific to a particular AOKI ISBM model but there is a Pacwel unit available for the majority of the more popular AOKI models.

Given the worldwide success of Pacwel’s AOKI take out units, a range of units for the ASB ISBM’s is now being designed. Click here for Pacwel Take Out Unit Manual

Moulding Machine Tool

Cam Plas expertise in moulding performance and design requirements in the extrusion and injection stretch blow processes has led to them extending their offerings to the supply of quality cost competitive mould manufacture with excellent back up and support facilities.

Reviews

There are no reviews yet.